After some considerations about smart watches I finally decided to buy a Pebble this summer (some weeks before the price drop to 99$). It worked just fine and I finally got notifications for phone calls I cared about, emails, messages (thanks to Pebble and YaNC).

Everything worked until I start getting some weird behavior on my Pebble screen: random pixels, some white/black line. Changing the watch-face usually solved the issue, but it started getting worst to the extent the screen was no more readable. Getting a notification and being unable to read it was totally making my Pebble not usable. Even just reading time and date started to be odd.

I filed a RMA and Pebble, after a simple check and a few emails, sent me a new watch - without asking me back the faulty one (I suppose it's not money savvy for them to pay also the return shipment and try to refurbish it).

So on Monday I'll receive the replacement, while I still have the old one with the screen tearing problem. I already planned to tear it apart and try to fix it (actually it's completely unusable, as you can see in the pictures, but squeezing it was making the screen works good), and after reading a post in Pebble blog about a fix for the steel version (see the post here, thanks to Harry Teicher) I decided to give it a try without waiting for the RMA replacement.

If the fix was working for the steel, I supposed it could work also in the original Pebble, so I gave it a try. First you need the right tools. A Torx (6-point star-shaped pattern) screwdriver (I used a T5 Torx) and something (a plastic small knife) to help in opening it without leaving scratches.

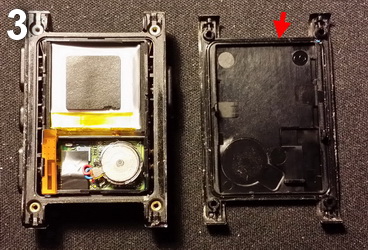

Unscrew the four screws at the corners on Pebble's back (see picture 1). If you don't have screws you've a glued model - you can try to warm your watch and force it open, but from the video a saw on the net it usually result in a mess. Then gently push the plastic tool in the side slit and use it as leverage until you hear a "tick" and the plastic back pops out. Proceed along the slit and free one side, then do the same on the other. Be careful not to pull too much the back cover: there's a little round part (the vibrator I suppose) that's glued to the back too, and pulling the back will result in snapping the two tiny wires of the vibrator (picture 2). To proceed, use the plastic tool to detach the vibrator from the back before completely pull away the cover.

Here you can find the high resolution version of the above images.

Once done, I had a look at the space inside and I prepared two tiny pieces of polyethylene (the one you find in servers' packaging - I prefer Dell's polyethylene, but I'm sure IBM or HP will be good anyway ;-P) to fit the space (picture 4 - green part will go up touching the back cover once in place). The polyethylene, being pressed by the cover once screwed back, will apply pressure on the screen connector (that's the part that generate the problem - the pressure will keep the contacts always connected).

Put the cover back in place after putting some silicone grease on it (not necessary bur recommended - will keep your watch sealed and waterproof - anyway, Pebble already has a rubber seal on the back cover - see picture 3), push it and put the screws.

Now I've a working Pebble on my wrist. It's actually running without any issue - will see the next days if the fix is permanent or not. Considering it takes a few minutes and two pieces of polyethylene, I think trying this fix on a Pebble with the screen tearing problem is definitively worth it.

Comments

Leave a Comment